Osmium is a dense, bluish-white transition metal in the platinum group, primarily used in alloys and specialized industrial applications due to its extreme hardness and high melting point. Understanding the production cost of osmium is crucial for industries that rely on this rare and valuable metal. This article provides a comprehensive analysis of the factors influencing the osmium production cost process, including raw material acquisition, extraction processes, labor, energy consumption, transportation, and regulatory compliance.

Overview of Osmium Production

Osmium is not mined directly but is typically recovered as a by-product of nickel and platinum mining. The production process involves several key steps, each contributing to the overall cost:

- Raw Material Acquisition: Osmium is extracted from ores that also contain other platinum group metals (PGMs).

- Extraction and Refining: The ores undergo complex refining processes to separate osmium from other metals.

- Purification: Further purification processes are required to obtain high-purity osmium.

- Forming and Packaging: The purified osmium is then formed into usable shapes and packaged for distribution.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/osmium/request-sample

Key Factors Influencing Osmium Production Cost

1. Raw Material Costs

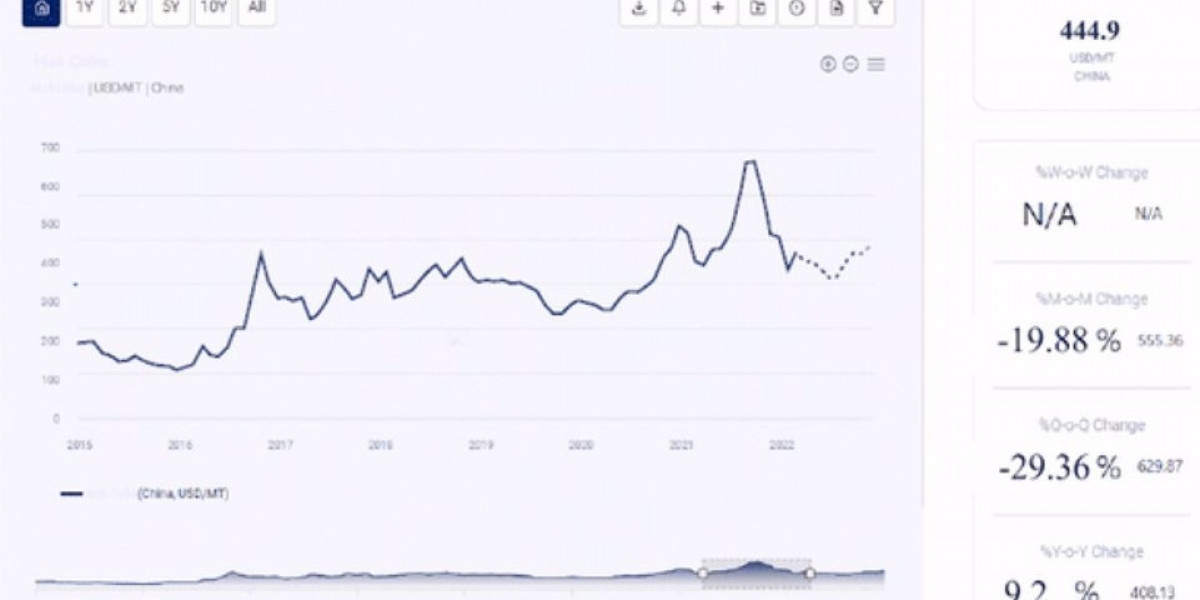

The primary sources of osmium are nickel and platinum ores. The cost of these ores is a significant component of osmium production.

- Nickel and Platinum Ores: The price of these ores fluctuates based on global market demand and supply conditions. Osmium content in these ores is typically very low, making the extraction process cost-intensive.

- Cost: Approximately $1,000 to $1,500 per ton of ore, depending on the metal content and market prices.

2. Extraction and Refining Costs

The extraction and refining process for osmium is complex and involves several steps, including smelting, chemical leaching, and precipitation.

- Smelting: The ores are smelted to concentrate the PGMs, including osmium.

- Cost: Approximately $200 to $500 per ton of ore.

- Chemical Leaching and Precipitation: Chemical methods are used to leach osmium from the concentrated ore, followed by precipitation to isolate osmium.

- Cost: Approximately $300 to $700 per ton of ore.

3. Purification Costs

Purification of osmium involves additional chemical processes to remove impurities and achieve high-purity osmium metal.

- Chemical Purification: Methods such as distillation or precipitation are used to purify osmium.

- Cost: Approximately $500 to $1,000 per kilogram of osmium.

4. Labor Costs

Labor costs vary depending on the region and the complexity of the production process. Skilled labor is required for the extraction, refining, and purification processes.

- Labor Costs: Approximately $50,000 to $100,000 per year per skilled worker. The total labor cost per kilogram of osmium can range from $500 to $1,000, depending on the efficiency and scale of the production operation.

5. Energy Costs

Energy consumption is a significant component of osmium production costs, particularly for processes involving high temperatures and pressures.

- Electricity: Used for operating machinery, pumps, and other equipment.

- Cost: Approximately $0.10 to $0.30 per kilowatt-hour (kWh), varying by region.

- Fuel: Required for smelting and other energy-intensive processes.

- Cost: Approximately $50 to $150 per ton of fuel, depending on the type and efficiency.

6. Transportation Costs

Transportation costs include expenses associated with moving raw materials to the production site and transporting the final product to customers. These costs depend on the distance between the production site and the market, as well as the mode of transportation used (e.g., truck, rail, ship).

- Transportation Costs: Approximately $50 to $200 per kilogram, depending on the distance and mode of transport.

7. Environmental and Regulatory Costs

Compliance with environmental regulations and the implementation of safety measures add to the overall production cost. This includes costs related to waste management, emission controls, and worker safety.

- Regulatory Compliance: Approximately $50 to $150 per kilogram of osmium, depending on the region and the stringency of regulations.

Total Estimated Production Cost

Combining these factors, the total production cost for osmium can be estimated as follows:

- Raw Materials: $1,000 to $1,500 per ton of ore

- Extraction and Refining: $500 to $1,200 per ton of ore

- Purification: $500 to $1,000 per kilogram

- Labor: $500 to $1,000 per kilogram

- Energy: $0.10 to $0.30 per kWh

- Transportation: $50 to $200 per kilogram

- Environmental and Regulatory: $50 to $150 per kilogram

Total Estimated Production Cost: $2,600 to $5,000 per kilogram, depending on various factors such as efficiency, location, and market conditions.

Conclusion

The production cost of osmium is influenced by multiple factors, including raw material acquisition, extraction and refining processes, labor, energy consumption, transportation, and regulatory compliance. Understanding these components helps in optimizing the production process and managing costs effectively. As demand for osmium continues to grow across various specialized industries, producers must continually seek ways to enhance efficiency and reduce costs to remain competitive in the global market.